Control Your Molds

Many companies wrongly assume they will own the molds/tooling and accompanying IP for products made overseas. But without clear contracts, you likely don’t and there is a good chance you will find yourself unable to switch product suppliers even if your product supplier raises prices through the roof and produces terrible products.

This post explains how you can lose control of your molds and IP and what you can and should do to prevent this.

Companies that engage in overseas outsource manufacturing need to retain control over their molds/tooling at all costs. To accomplish this for our clients, our international manufacturing lawyers focus on two issues when drafting mold/tooling provisions that are part of a larger contract (such as a manufacturing agreement or a product development agreement) or that stand alone as part of a mold/tooling ownership contract.

First, we want to make clear that our client owns the molds/tooling, period. Our contracts typically provide that the overseas factory (be it in Taiwan, Thailand, Mexico, Spain, Poland, China or wherever) can use the molds only for producing our client’s product and not for producing product for any other party. Second, we write our contracts to make clear that when our client chooses to move its production to a different factory, it will have the right to take its molds/tooling to the new manufacturing location. Negotiation of these terms is usually quite difficult since manufacturers have a strong incentive to hold molds “hostage” to prevent their foreign buyers from moving their manufacturing to a new factory. The only way to succeed is with a standalone mold ownership agreement or mold ownership provisions inserted into a written manufacturing or product development agreement.

Second, we write our contracts to ensure that our client owns all IP inherent in the molds. In some products, the form embodied in the mold is in fact the entire value of the product. Take for example a complex part used to manufacture a turbine or a jet engine. After all the engineering and testing is complete, all that remains is a single part produced by casting into one or more molds. In this situation, the molds embody the entire intellectual property in the part and so the party that owns or controls the intellectual property in the molds essentially controls the product. More importantly, if no party owns any IP in the molds, the molds are effectively open source. And if no one owns any IP in the molds or the product, your manufacturer is free to make your product.

As manufacturing overseas has become more complex, molds for products have become correspondingly more complex, as well. In many cases, the mold embodies most or all of the intellectual property in the product. The following two examples highlight this. First, in some products, the interior mechanism is based entirely on open-source hardware. The external enclosure surrounding the mechanism is therefore the primary protectable IP for the product. The IP resides entirely in the molds used to manufacture the product case. The “look and feel” of the enclosure becomes the identity of the product, and if that “look and feel” is not protected, the foreign company that designed the enclosure owns no IP related to the product. Without the IP in the molds, your overseas factory can freely copy your product.

Mold Fabrication Shops

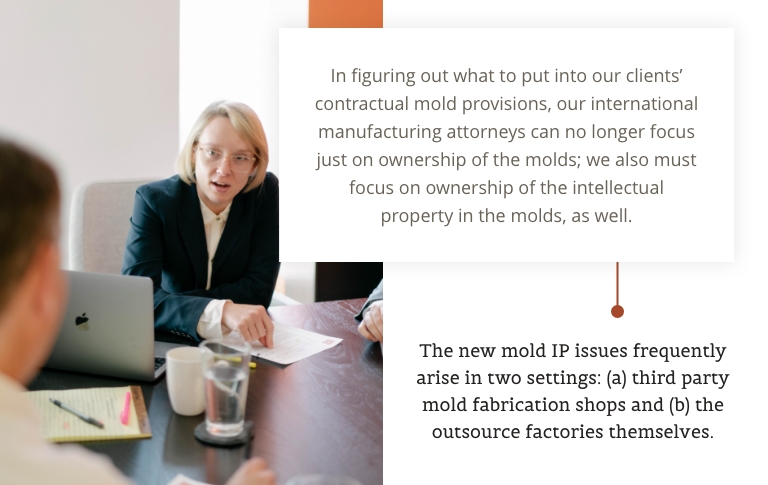

Factories that engage in contract manufacturing have figured all of this out, making protecting molds increasingly difficult. In figuring out what to put into our clients’ contractual mold provisions, our international manufacturing attorneys can no longer focus just on ownership of the molds; we also must focus on ownership of the intellectual property in the molds, as well. The new mold IP issues frequently arise in two settings: (a) third party mold fabrication shops and (b) the outsource factories themselves.

The issues that typically arise with mold fabrication shops arise because of a change in procedure that no one has really noticed. It is standard procedure to provide that the contract manufacturing factory making your product is responsible for fabricating the molds for the product as well. In the old days, the same factory almost always made the molds and the product. However, it has now become more common for your product manufacturing factory to outsource the mold fabrication to a third party as well. In many cases, even the design of the molds is outsourced to that third party.

What this means is that a mold agreement with your factory that has been drafted to control ownership of the molds and the IP in the product is compromised when the specifications and the responsibility for fabrication gets sent to a third party mold manufacturer. Given the economics of mold fabrication, it is not common for your mold fabricator to use your mold design for its own purposes, but it is common for them to sell copies of your molds to factories interested in cloning your product.

This type of product cloning is a thriving business in China and to a somewhat lesser extent in most other countries known for their contract manufacturing as well. Foreign product designers often wonder how a terrific copy of their product got to market before they themselves have even gone into full scale production. This usually happens because many mold manufacturers conduct a thriving trade in selling the “latest” molds. The factory you use to manufacture your product actually has an incentive to keep the mold for its own use since once it gets out into the world the molds will be used by your factory’s competitors. When this happens, the factory making your product will be damaged in much the same way as you will be. See Your China Factory as Your Toughest Competitor and China Manufacturing and the First to Market Fallacy.

The Factory that Makes Your Products

The fundamental issue with your own factory is the same as with your mold fabrication shop: who will own the IP in the resulting design? For the product, the question is who owns the design for the product. For the molds, the question is who owns the design in the molds.

Where the molds are the product, this becomes a core issue that cannot be ignored.

Our international dispute resolution lawyers usually see the following three basic problems after a series of molds has been made for a successful product:

1. The overseas product manufacturer announces a substantial increase in the price of the product. This is often a surprise to the product buyer, who expected its per unit product pricing to decrease as production increased.

2. The overseas product manufacturer is not able to keep up with increased production requirements. This is often a surprise to the foreign buyer, who had been assured by its product manufacturer that it had ample capacity to scale for any number of orders.

3. The increased production demands cause the quality level from the manufacturer to decline to unacceptable levels. This is often a surprise to the foreign buyer, who had expected quality to improve over time.

In response to any of the above three issues, the foreign buyer gives notice to its manufacturer that it intends to move production to a different manufacturer. In the past, the issues that arose at this stage mostly focused on ownership of the physical molds, an issue that usually can be resolved with a relatively simple mold ownership agreement. To the extent that a mold ownership agreement resolves the issues, this is old news.

However, the past few years have seen factories make arguments (like those below) that render the situation far more complex:

1. The factory says: “It is true you paid the fabrication fee for the molds, but that fee was only for the material costs and the time involved. In addition to that, we spent much time and money doing the CAD drawings and related specifications required to fabricate the molds, and we also spent engineering time integrating the molds into our production process. Before you can take the molds, you must compensate us for those costs. We won’t charge you a markup, but you must pay us for our out-of-pocket costs.” Then the factory provides an unreasonably high invoice for those costs, and if you do not pay it will hold your molds hostage. This has become almost standard practice in outsource manufacturing in China and to a lesser extent in other countries as well, especially in those countries where many of the factories are Chinese-owned. It is therefore essential to have a written contract that makes clear the payments cover everything related to the molds and no additional payments will be required when the buyer seeks to take possession of the molds.

2. The factory says: “It’s true you own the molds, and you can take them whenever you want. However, we did all the design work on those molds, so we own the design embodied by the molds. We will give you a license to use the molds for production with another factory, but that license is limited. You cannot copy the molds, but we have the right to copy the molds and use them for our own production and to sell copies of the molds to third party factories.”

3. The factory says: “We did all the design work for the molds, so we own that design, and we already registered a design patent in the molds because we are the inventor for patent purposes. It does not matter that you paid us for the molds because we are the inventor, and our design patent protects us. You can have the physical molds, but if you want to use those molds for production at a different factory, you must pay us a royalty fee.” This royalty is then quoted at a price so high that you cannot economically have your product produced at a third-party facility

Products Held Hostage

The more honest factories make the situation clear during the negotiation process. The foreign buyer pays for fabricating the mold, but that payment does not convey any ownership interest in the molds to the foreign buyer. The factory does the design work, and the factory owns the molds. The factory will agree to use the molds only for producing the product for the foreign buyer; however, the foreign buyer has no right to move the molds to any other factory. Some factories will say that you are free to make new molds at your new factory, but some will assert ownership to the mold design and not allow you to have copies made at the new factory. In other words, the factory is clear from the beginning that it intends to hold the foreign buyer hostage by not allowing it to use another manufacturer for its product. With tariffs and duties and sky-high shipping costs increasingly leading companies to seek to move their production elsewhere, our lawyers are getting a massive number of calls from companies blocked from moving their production despite crippling price increases. We have many strategies for helping such companies, but none are nearly as good nor nearly as cheap as using good contracts that prevent this problem from arising in the first place

Mold IP issues when dealing with third-party mold fabricators

The issues that typically arise with mold fabrication shops arise because of a change in procedure no one has really noticed. It is standard procedure to provide that the factory making your product is responsible for fabricating the molds for the product. In the old days, the same factory almost always made the molds and the product. However, it is now at least as common for the product factory to outsource mold fabrication to a third party. In many cases, even the design of the molds is outsourced to that third party.

What this means is that a mold agreement with your factory to control ownership of the molds and the IP in your product is compromised when the specifications and responsibility for mold fabrication is with a third-party mold manufacturer. Given the economics of mold fabrication, it is not likely the mold fabricator will use the mold design for its own purposes. Rather, the fundamental risk is that the mold manufacturer will sell copies of your molds to other factories interested in cloning your product.

This type of cloning is a thriving business in China and around the world. With manufacturing leaving China for places like Vietnam, Cambodia, Malaysia, Mexico, Thailand, India, etc., we are “seeing” many instances where a mold made in one country ends up in China being used for product cloning. We are also seeing many instances where the product mold is made in China for a product made somewhere like Vietnam and the foreign company failed to protect its IP in both countries, as is virtually always necessary.

Foreign product designers often wonder how a terrific copy of their product got to market before they have gone into full scale product production. This is how it happens: the mold manufacturers conduct a thriving trade in selling the “latest” molds. Though it is common to blame the product factories for this leakage, this blame is often misplaced. Your product factory often has an incentive to keep your mold for its own use since once your mold gets out into the world it will be used by your factory’s competitors. When this happens, your factory is damaged in much the same way as you because its production of your product will likely decrease or end.

Though losing one’s molds via a third-party mold fabrication shop is an enormous risk, few foreign product designers and virtually no factories in Asia make much effort to control the mold fabricator. Clearly drafted written contracts dealing with this issue are rarely entered into between the Asia factory and the mold fabricator. The foreign product designer not only does not usually enter into any sort of contract with the mold fabricator, the foreign product designer normally does not even know the identity of its mold fabricator. It usually just assumes its product factory is also its mold factory.

Because many product designs are protected primarily as trade secrets , the release of the design to a third-party mold fabrication shop with no written agreement breaks the secrecy in the product and thereby eliminates any trade secrecy protection. Third- party mold production leaves a gigantic hole in IP protection that can and should be closed through a simple set of contracts.

Though losing one’s molds via a third-party mold fabrication shop is an enormous risk, few foreign product designers are aware of this risk and even fewer know what needs to go into a contract to prevent this leakage. The foreign product designer rarely even knows the identity of its mold fabricator. They mostly just assume it is the factory manufacturing the product that will be making their molds as well. This leaves a giant hole in their IP protection that can and should be closed by using a relatively simple set of contracts.

Also consider the issue of patent protection. To acquire a patent anywhere in the world you must show that you invented the item. In a case where the design of the mold has been outsourced to a third-party mold fabrication shop, who actually invented the item can become unclear. Is it the foreign product designer who developed the basic idea? Is it the product manufacture that did some preliminary drawings? Or is it the mold fabricator that did the detailed drawings and produced the final working model? Or is it all three, each entitled to a percentage of the patent? Our law firm’s international litigation attorneys have handled too many cases where this issue was not clear. With this sort of tripartite structure, the usual answer is that no one owns any IP in the molds. There are no patents and no trade secrets. This often means no one owns any IP in the product itself either. This frequently leads to disasters in commercializing the product.

For the product, the question is who owns the design for the product. For the molds, the question is who owns the design in the molds. Where the molds ARE the product, this becomes a core issue that cannot be ignored.

And yet, with this sort of tripartite structure (buyer, mold fabricator and product manufacturer), the usual answer is that no one owns any IP in the molds: no patents, no trade secrets. Often this means nobody owns any IP in the product itself. This can be a disaster for the foreign product company.

How to Protect Your Molds and Tooling

All too often companies come to our law firm after they have signed a contract that essentially turns over their products and IP to their foreign manufacturer. See Giving Your IP to China Out of Love and How to Give Away your IP Without Realizing It. These product and IP “gifts” usually happen because the foreign buyer did not understand what they had signed, oftentimes because it was in a foreign language they don’t understand and did not get translated. Other times they simply do not understand what they had signed no matter the language. Sometimes they tell us they thought the contract they signed was “standard.” These mistakes are incredibly common and pretty much every week one or more of our international lawyers gets contacted by a company that has fallen victim to this.

Product designers and buyers need to learn how to protect their molds and their mold designs. The simplest way is via enforceable written contracts that provide protection. Foreign product designers and buyers need to deal with the above issues before they decide to move their manufacturing elsewhere or before the price increases they face force them to do so. At the most basic level, the key is to be able to recognize when a factory is intending to hold your molds “hostage” and to do a cost-benefit analysis of whether it makes sense to proceed or walk away. Our international manufacturing lawyers would tell you that it usually makes sense to walk away

Conclusion

If you are a product designer or manufacturer, you need to recognize and plan for the reality of losing control over your molds and tooling and even their IP when producing overseas. To prevent this, you must arm yourself with written agreements that clearly establish your ownership rights and you must do this before you embark on international production.

Protect your molds and tools or risk losing the core of your business. Don’t become another cautionary tale. Work closely with qualified legal counsel to craft agreements with enforceable terms in the relevant jurisdiction. Taking these proactive steps will help secure your molds, tooling, and IP through the entire production process.

What are you seeing out there?